Structural Ceramics & Composites

Structural ceramics are often referred to as advanced, technical, or fine ceramics, owing to their intricate composition and remarkable characteristics. They demonstrate endurance against high mechanical, thermal, and tribological stresses, while also displaying exceptional resilience to corrosive environments and elevated temperatures. Initially, the focus was primarily on oxide ceramics like alumina, zirconia etc. However, as the ceramic processing techniques have evolved over time, the scope of structural ceramics has broadened to include carbides, nitrides, silicides, borides, and their composites. Structural ceramics are utilized across numerous commercial applications, including gas turbines, welding nozzles, heat exchangers, heat pipes, valves, cutting tools, turbochargers, crucibles, dentistry, bone and joint replacement prostheses etc., to name a few.

Over the years, research conducted here at the Department of Ceramic Engineering has delved into various aspects relevant to structural ceramics and composites. This includes research exploring toughened alumina, nano magnesia-carbon refractory bricks for high-temperature structural applications, zirconia-based ceramics for dental implants, structural component and ceramic-based systems for solid oxide fuel cells, among other areas of study.

Associated Faculty Members :

- Prof. Vinay Kumar Singh

- Dr. Manas Ranjan Majhi

- Dr. Mohammad Imteyaz Ahmad

- Dr. Kundan Kumar

Recent Publications:

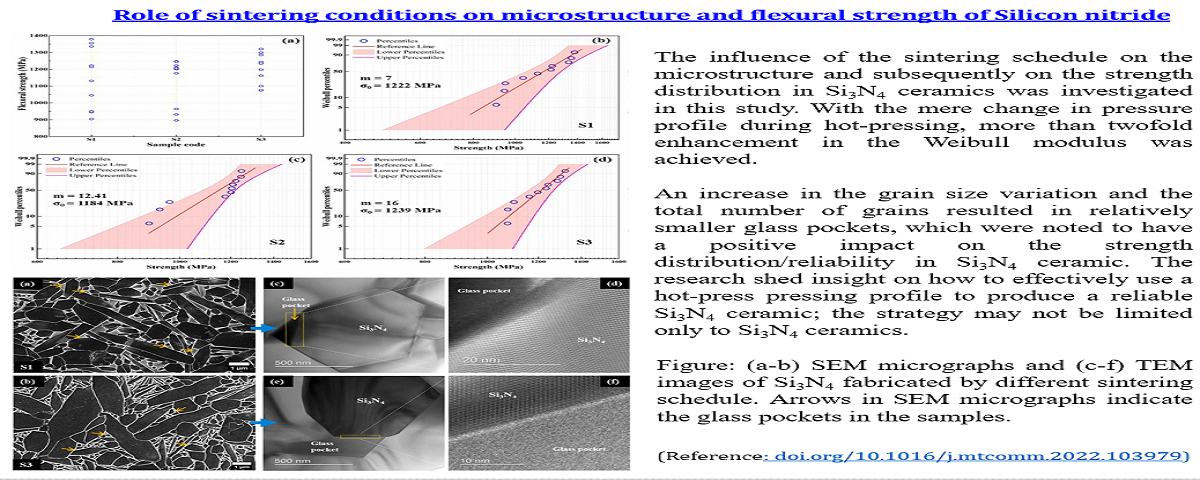

- Materials Today Communications, 32, 103979, 2022 doi.org/10.1016/j.mtcomm.2022.103979

- Journal of the European Ceramic Society, 43 (5), 2069 2022 doi.org/10.1016/j.jeurceramsoc.2022.12.003

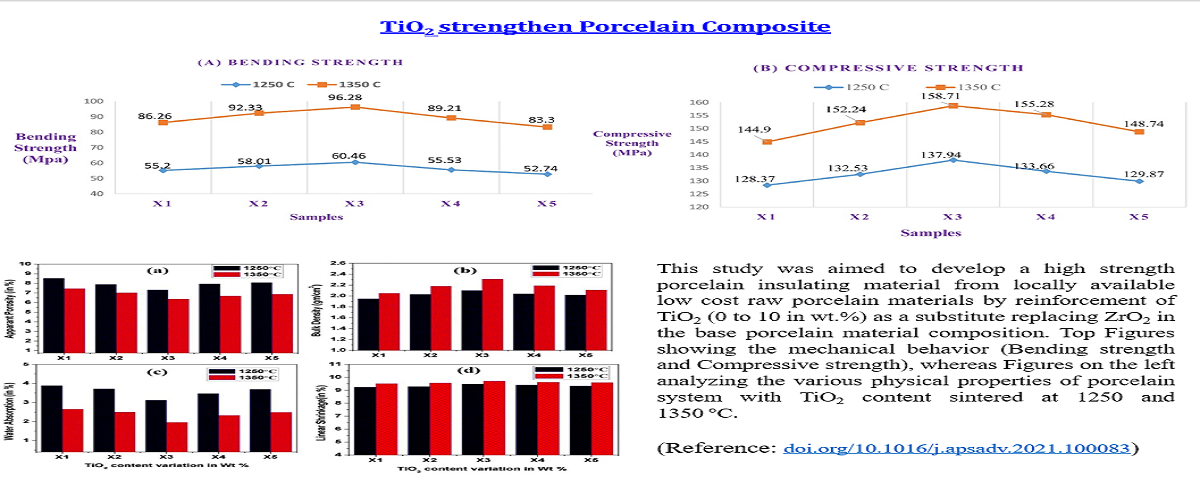

- Applied Surface Science Advances 4 (2021) 100083 doi.org/10.1016/j.apsadv.2021.100083

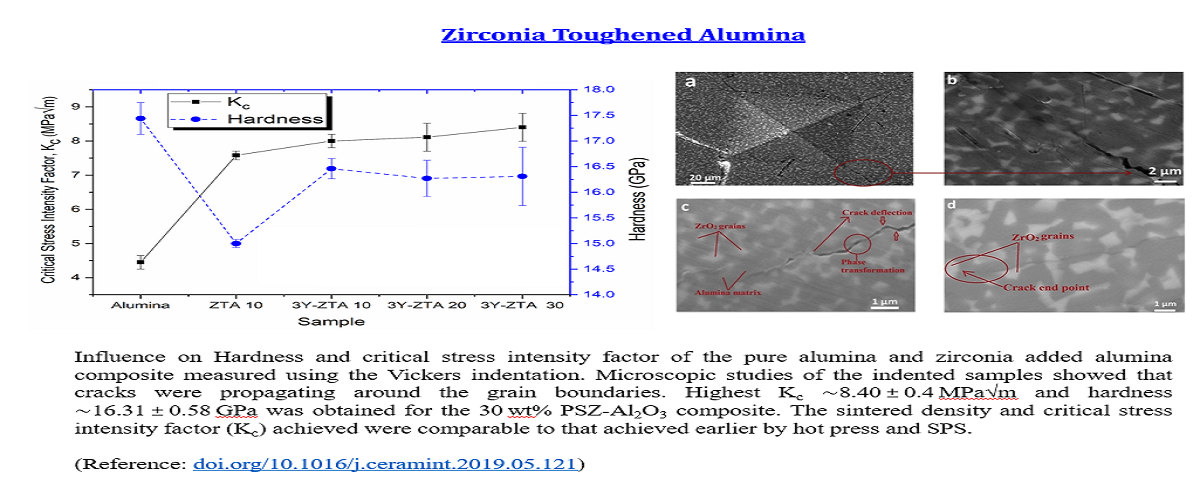

- Ceramic International, 45 (13) (2019) 16054-16061 doi.org/10.1016/j.ceramint.2019.05.121