Additive Manufacturing Section

Metal 3D Printer Model -EOS M 290)

Company Name: Electro Optical Systems(EOS)

- Working: The EOS M 290 has the most extensive range of validated materials and processes on the market. EOS metal materials are designed specifically for DMLS and are quality controlled. EOS processes are validated ensuring consistent and repeatable part quality. Explore below which metal materials and processes are compatible with the EOS M 290.

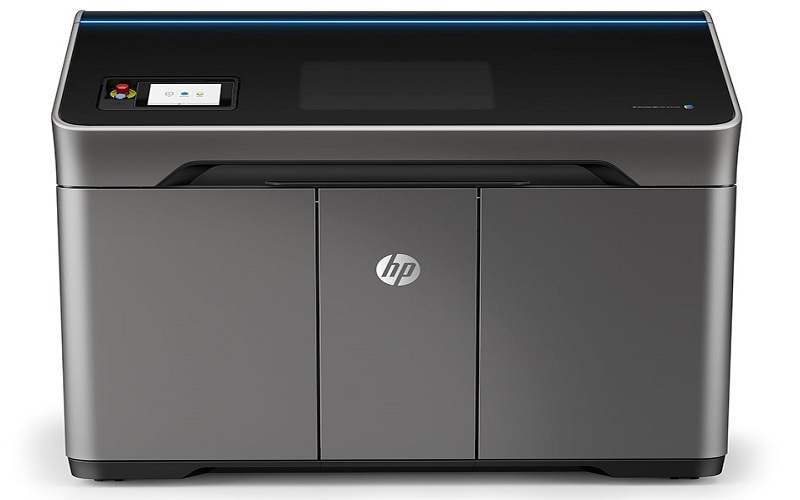

Colour 3D Printer Model -HP Jet Fusion 580

Company Name: - H.P

- Working: 3D printing offers a much higher

level of freedom in terms of design than

any other traditional manufacturing

technology. Designers and engineers can

benefit from this, and use new geometries

and concepts that were not feasible

before. However, in order to optimize the

design to be printed with MJF, you should

be aware of some characteristics of the

printing process and its capabilities, as this

could help to get the best of the

technology.

The design and printing guidelines offer an overview of the steps to follow before sending a job to print, from file preparation to the considerations that should be taken into account in the design of the parts and the orientation of them in the build chamber to optimize the final part quality and printing performance

Composite 3D Printer Model - MARK X 7(Gen 2)

Company Name: – Mark Forged

- Working:A game changing way to get industrial-grade parts in hours, not weeks, the X7 carbon fibre 3D printer enables engineers and designers to fundamentally improve manufacturing operations at light speed.

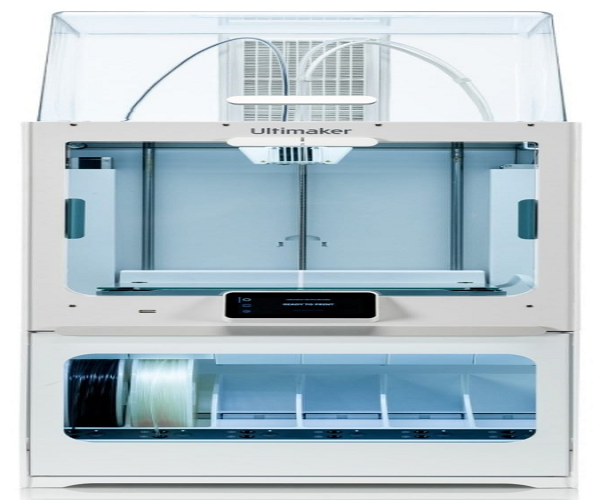

Ultimaker 3D Printer Model – Ultimaker S5

Company Name: – Nobabeans Prototyping Labs. LLP

- Working:The S5 makes it easy to click and print with an unrivalled range of materials so your 3D printing applications can meet the demands of the real world. Choose from advanced engineering polymers, glass or carbon fibre composites, recycled filaments, and stainless steel.

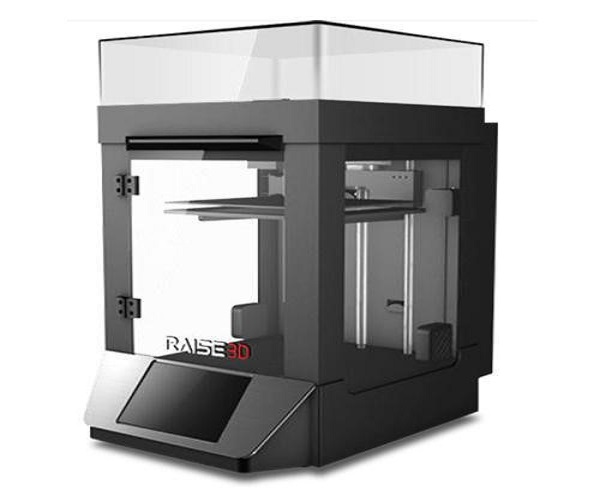

Smart Mini 3D Printer Model – RxP 2200

Company Name: – RSISE 3D N1

- Working: Raise3D Printing Build

Surface uses BuildTak as its printing

surface. BuildTak is ideal as 3D printing

surface for Raise3D printers, and is well

received by 3D printing enthusiasts and

manufacturers alike. BuildTak is sturdy

and durable, so it can more effectively

protect the build plate. BuildTak is

heat-resistant and strong, meaning it

can be reused many times, and is

suitable for printing a variety of

filaments.

The Raise3D Printing Build Surface will adhere firmly to the build plate, so it will not become dislodged or fall off during the printing process. It is also very easy to remove the model from the printing plate. Raise3D Printing Build Surface is easy to clean, you can just wipe it with warm water or alcohol. Please avoid using solvents such as acetone for cleaning.

Multi Layered PCB Prototyping

Company Name: PhotoLaser S4- LPKF

- Working: The ProtoLaser S4 is a valuable tool in the electronics laboratory. The compact laser system produces precise, fine structures for demanding PCBs in a very short time - as single pieces or small series, without masks or tools. Using a special process, the ProtoLaser S4 quickly removes large copper areas from laminated substrates such as FR4. The ProtoLaser S4 also delivers excellent results on special materials for RF applications.

C.N.C. Lathe Machine

C.N.C. Lathe Machine ModelStallion -100 SU

Company Name:H.M.T

- Working: Facility for cross and longitudinal

chip conveyor.

»Single piece monolithic cast iron bed base

structure for the highest rigidity and

damping.»450 Slant bed for easy chip flow and

better heat dissipation. »8-Station servo tool turret.

»Programmable tailstock with built-in

rotating centre »Short main spindle – ensures rigidity.

»Optional C-axis and driven tool turret.

»Direct coupled servomotors

»Highly efficient main drive with less than

20% idle power at maximum speed, thus

reducing cost.

»Hardened and ground integral guideways. »Separate lost lubrication oil collection to prevent mixing of lubrication oil with coolant.

C.N.C. Lathe

Company Name: -Concept Turn 260-EMCO Group

- Integrated industrial PC with 21,5" touch screen (MOC-Touch); Easy2control user interface; Interchangeable controls (WinNC); Stable, industry-standard gray cast iron construction; Various clamping devices and tool holder packages; MOC: integrated PC; High machining precision; Bar-stock diameter 25 mm: with bar-stock loader ideal for small part production; Digital drives with high driven power; Extraordinary dynamics; Thermostability for highest precision and contour fidelity; Driven tools with high machining power for drilling, thread and milling operations.

C.N.C. Milling Concept ModelMill 260

Company Name:– EMCO Group

- Working:: Integrated industrial PC with 21,5" touchscreen (MOC-Touch); Easy2control; user interface Interchangeable controls (WinNC)Stable, industry-standard gray cast iron construction; Various clamping devices and tool holder packages; MOC: integrated PC; High machining precision; Bar-stock diameter 25 mm: with barstock loader ideal for small part production; Digital drives with high driven power; Extraordinary dynamics; Thermostability for highest precision and contour fidelity; Driven tools with high machining power for drilling, thread and milling operations; Many automation possibilities.

C.N.C. Lathe Train Master ModelCNCT -100 (s)

Company Name: – H.M.T

- Working: Compact table top model, most ideal for training institutes. Machine with higher power suitable for steel cutting. Step less AC drive for headstock. Hardened and ground spindle runs in precision antifriction bearings. Conventional FANUC / SIEMENS CNC system controlled machine best suited to technical educational institutions and small shops. Recirculating Ball screw and nut arrangement for longitudinal and cross axis.

C.N.C. Milling Trainmaster Model VMC 200 T

Company Name: – H.M.T

- Working: An economical and user friendly

PC based system to meet Training

requirements of all Training Centres,

Technical and Educational Institutions in

CNC machine tools operation &

programming. Provides a comprehensive

range of CNC functions for both Vertical

and Horizontal modes of operation, with a

CRT monitor and many more advanced

features.

PC based CNC system. Compact table top model, most ideal for training institutes. Step less DC drive with RPM and load indication for spindle. Hardened and ground spindle runs in Precision antifriction bearings. Economical CNC system best suited to educational institutions.

C.N.C. Milling ModelTrainer Type

Company Name: –SVP Laser

- Working: Vertical mini milling machines are made in the USA and feature either precision-rolled ball screws or leadscrews, and hand wheels graduated in thousandths of an inch (.001") or hundredths of a mm (.01 mm). SVS mini milling machines can cut metal, wood, or plastic and come in two different sizes: table top (10" and 12" bases) and benchtop (14" and 18" bases).

C.N.C. Turning ModelTrain Master

Company Name: –Sherline

- Working: An entry level CNC automated Lathe machine with sophisticated capabilities. It is used for Prototyping and Light production. 2D / 3D designs can be fabricated directly from CAD design.

C.N.C. Laser Cutting ModelEVA – II

Company Name: – Mehta CAD CAM Systemsm Pvt. Ltd.

- Working: A CNC laser cutter is a piece of computer numerical control (CNC) equipment that uses a focused, highpowered laser beam to mark, cut, or engrave a material to form custom shapes. Its unique design and operation make it highly accurate, especially when cutting intricate shapes and small holes.

Hyrel 3D Printer ModelHydra 16 AS

Make: – Hyrel

- Working: Hyrel believes innovation is a team effort. Our customers use our products with the confidence that we will always be here and available to help them. Whether it’s a technical issue or a tricky print job, we work with you to find a fix.

Raman Microscope / Spectrometry ModelAlpha300RA

Make: –WITec, Germany

- Working: Raman spectroscopy is a spectroscopic technique typically used to determine vibrational modes of molecules, although rotational and other low-frequency modes of systems may also be observed. Raman spectroscopy is commonly used in chemistry to provide a structural fingerprint by which molecules can be identified.

High Temperature FurnaceModelUltrahigh Temperature

Make: –AntsProsys

- Working: Just as their 2000°C counterparts, these compact tube furnaces with SiC rod heating and integrated switchgear and controller can be used universally for many processes. With an easy to replace working tube as well as additional standard equipment options, these furnaces are flexible and can be used for a wide range of applications.

Muffle FurnaceModel1400 Deg. Celsius

Make: –AntsProsys

- Working: A muffle furnace is a high-temperature heating device used in laboratories and industries for material testing, heat treatment, and isolating the sample from direct contact with heating elements for uniform heating and precise thermal processing.

High Capacity Muffle FurnaceModel1800 Deg. Celsious

Make: –AntsProsys

- Working: A muffle furnace is a high-temperature heating device used in laboratories and industries for material testing, heat treatment, and isolating the sample from direct contact with heating elements for uniform heating and precise thermal processing.

Large Format FDM 3D PrinterModelPratham 6.0

Make: –Make 3D

- Working: FDM (Fused Deposition Modeling) 3D printing works by extruding heated thermoplastic filament layer-by-layer onto a build plate, following a digital model, to create a 3D object. The process begins with a 3D CAD (computer-aided design) model. Slicing software divides the digital model into numerous layers (slices) and outputs a G-code file for the printer. A spool of thermoplastic filament (like PLA, ABS, etc.) is loaded into the printer. The printer heats the filament to a semi-liquid state, then extrudes it through a nozzle. The nozzle moves along the build plate, depositing the molten material in thin layers, following the instructions in the G-code file.

As the material is deposited, it cools and solidifies, forming the next layer. For overhangs or complex geometries, the printer may deposit support structures (also made of thermoplastic or a soluble material) to prevent warping or drooping. Some printers have multiple extruders, allowing for printing with different materials or colours, or for printing support structures with a different material.

DLP 3D PrinterModelPhrozen Sonic Mega 8K S

Make: –Hydrotech 3D Chennai

- Working: Phrozen Sonic Mega 8K S High-Speed 3D Printer for Mass Model Production Experience the power of high-speed 3D printing with Phrozen Sonic Mega 8K S, designed for efficient mass model production. This cutting-edge 3D printer boasts a rapid printing speed of 400 layers per hour, optimizing productivity like never before. Embrace faster printing and increased efficiency.

Achieves faster printing up to 400 layers per hour printing speed with the new high-speed mainboard. Higher Productivity: The 15” large printing area enables efficient mass production, allowing you to print more in a single batch. Maximize your resin usage and simplify post-printing clean-up with the built-in Resin Drip Hanger. It reduces wastage by allowing excess resin to drip back into the vat, making cleaning a breeze and enhancing the overall user experience.

Micro Electrical Discharge Machining Model HX50P

Make: –Hexon Instruments Private Limited

- Working: A portable micro-EDM machine removes material from electrically conductive workpieces by creating precisely controlled, high-temperature electrical sparks between a tool electrode and the workpiece. These sparks melt and vaporize material in tiny craters, with the debris flushed away by an insulating dielectric fluid.

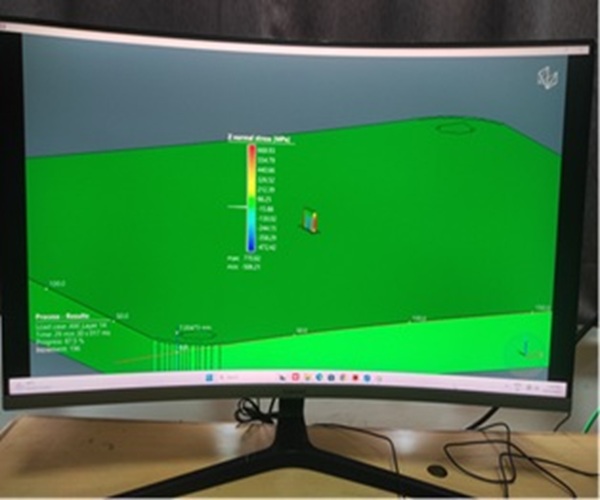

Simufact Suite ModelSimufact(Additive, Welding & Casting)

Make: –Hexagon

- Working: Modeling and simulation software creates a virtual, mathematical representation of a real-world system, allowing users to test scenarios, predict behavior, and optimize designs in a risk-free, virtual environment before costly physical prototyping or implementation. The process involves building a mathematical model of the system, running simulations using the software's algorithms to observe its dynamics under various conditions, and then analyzing the resulting data through visualizations and reports to gain insights and make informed decisions.

Ultimaker 3D Printer ModelUltimaker S5

Make: –Nobabeans Prototyping Labs. LLP

- Working: The S5 makes it easy to click and print with an unrivalled range of materials so your 3D printing applications can meet the demands of the real world. Choose from advanced engineering polymers, glass or carbon fibre composites, recycled filaments, and stainless steel.

Smart Mini 3D Printer ModelRxP 2200

Make: –RAISE 3D N1

- Working: Raise3D Printing Build Surface uses BuildTak as its printing surface. BuildTak is ideal as 3D printing surface for Raise3D printers, and is well received by 3D printing enthusiasts and manufacturers alike. BuildTak is sturdy and durable, so it can more effectively protect the build plate. BuildTak is heat-resistant and strong, meaning it can be reused many times, and is suitable for printing a variety of filaments. The Raise3D Printing Build Surface will adhere firmly to the build plate, so it will not become dislodged or fall off during the printing process. It is also very easy to remove the model from the printing plate. Raise3D Printing Build Surface is easy to clean, you can just wipe it with warm water or alcohol. Please avoid using solvents such as acetone for cleaning.

Inverter Air Plasma Arc Cutting MachineModelCUT – 100 (IGBT)

Make: –CRUX WELD

- Working: Inverter plasma cutters rectify the mains supply to DC, which is fed into a high-frequency transistor inverter between 10 kHz to about 200 kHz. Higher switching frequencies allow smaller transformers resulting in overall size and weight reduction.

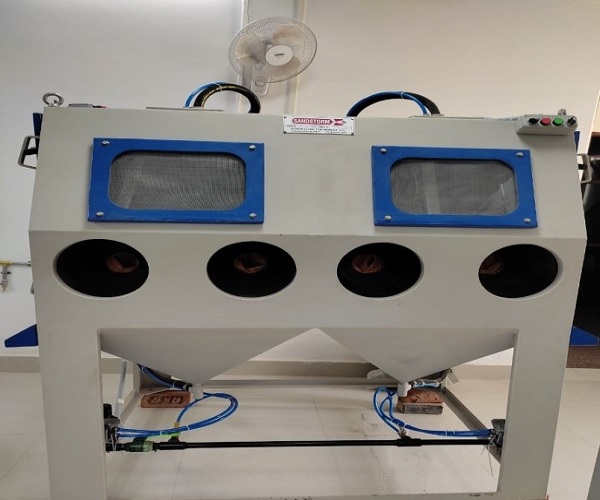

Post Processing & Finishing Section